The benefits of working with an Electronics Manufacturer with a conformal coating PCB service

Working with an electronics manufacturer that offers a conformal coating PCB service can provide numerous benefits. But to begin with, what is conformal coating? High quality conformal coating offers a protective layer to printed circuit boards (PCBs) to safeguard them against environmental factors. These include moisture, dust, salt, chemicals, temperature changes and abrasion. Without conformal coating, PCBs are at risk from corroding which can result in product malfunction.

Here are some of the benefits that come with working with an electronics manufacturer that offers a conformal coating PCB service:

A good electronics manufacturer with a conformal coating PCB service will be able to handle the complexity of the work

A conformal coating PCB service is one of the more challenging and complex electronic manufacturing services offered in-house. One of the factors is the delicate nature of the component parts used on a conformal coated PCB. These components may need more careful handling. Care also needs to be taken when oven curing the coating, to confirm that the heat will not damage components.

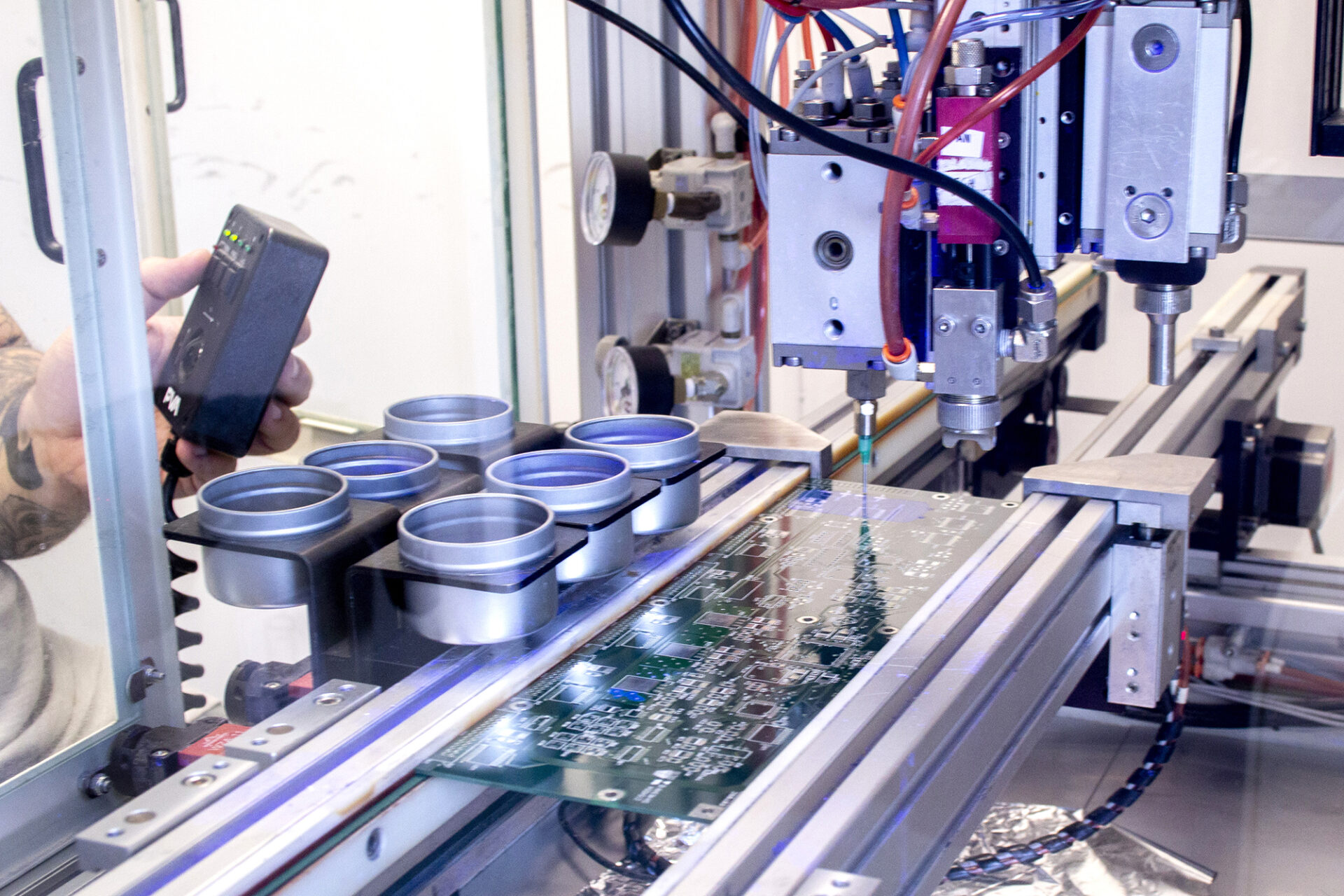

Sometimes, only certain areas or components on the board require coating. This is where a selective conformal coating machine comes in. Being able to use a machine in house to do this allows for improved accuracy, without the need for masking.

Once conformally coated, it is difficult to re-work boards so it is important to prepare carefully for a job in order to get it right the first time. When the conformal coating is added to protect the board there is a risk of sealing in foreign items. To avoid this boards must be washed beforehand, and dried properly to ensure no moisture or dust is trapped. FermionX uses a PBT Super Swash III Twingo supplied by Blundell to ensure boards are cleaned.

Always make sure you are working with an electronics manufacturer with a conformal coating PCB service who has good experience and knowledge.

An electronics manufacturer with a conformal coating PCB service will use the most suitable material for your job

The first step is to research and understand the most suitable coating material, whether that be silicone coating or acrylic resin coating. Making the right choice for the job ensures the best output. All of the conformal coating that we use and supply at FermionX have been previously put to the test in harsh environments. These include offshore oil rigs where they have to withstand moisture, salt and heat.

Working with an electronics manufacturer with a conformal coating PCB service will save you money

While there is an additional cost associated with conformal coating, it can ultimately be cost-effective due to the increased reliability and lifespan of the products that use PCBS.

Successful conformal coating will protect electronic components from external factors, preventing corrosion and extending the lifespan of the products that use them. This can reduce the need for costly repairs and replacement.

The accuracy of a human, yet the fast output of a machine, is how an accurate conformal coating machine should work. When undertaking larger scale jobs the gain in time savings is significant, and simultaneously this is translated into a saving in labor costs.

Conformal coating machines can offer faster, more competitive and more accurate results. So it is more beneficial to go to an electronics manufacturer that has an automated conformal coating service like FermionX.

A good electronics manufacturer with a conformal coating PCB service will take the time to fully understand your business needs

A good manufacturing partner will plan ahead and take the time to fully understand the needs of the customer. They will also support the customer as much as possible in the unlikely event of errors occurring after coating. At FermionX we are proud to have a dedicated Sales & Aftercare team who will follow up with customers. This way, we make sure we are offering the best support that we can.

At FermionX manufacturing, we will offer a free prototype to send to the customer to confirm it meets requirements before rushing into the job.

Working with an electronics manufacturer that offers conformal coating services allows for customisation of the coating to meet specific needs. This can include selecting the type of coating material, thickness, and application method.

We will not simply build to specifications, but rather support the customer through the process. This is especially important if they have not coated boards before. By ensuring that conformal coating is done right we protect our customers from long term problems.

To find out more about how FermionX can help with your conformal coating project, get in touch:

sales@fermionx.com

01903 524600